cab has expanded its product range in the area of diode pumped solid state laser systems with focus on the development of the Ytterbium fiber laser systems FL10 and FL20. Highest beam quality and pulse peak power offer the possibility to handle most diverse materials like steel, aluminum, precious metals and plastics.

cab has expanded its product range in the area of diode pumped solid state laser systems with focus on the development of the Ytterbium fiber laser systems FL10 and FL20. Highest beam quality and pulse peak power offer the possibility to handle most diverse materials like steel, aluminum, precious metals and plastics.

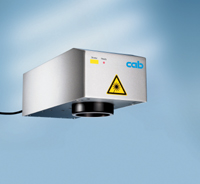

The laser marking systems consist of a laser source as desktop unit or 19 rack and a fiber-coupled galvo head for beam deflection. The marking head provides to integrate different plano-spherical lenses. The laser sources have integrated air-cooling and are designed modularly. The development of the FL series expecially focuses on industrial use.

The high focused laser beam and first pulse suppression provide marking results up to a resolution of 1200 dpi - perfect conditions for marking two-dimensional codes on sensitive materials. Even at high ambient temperatures the laser systems are working most precise and fast. Small fonts, graphics or Logos- everything is marked in correct position and true to the original.

The power output of the laser is reached by parallel connection of multiple diodes whose MTBF (mean time between failure) is more than 50.000 hours. Consequently, "trouble-free" control of single diodes as well as long operating life is attained, even at high environmental temperatures. Fiber laser systems are adjustment-insensible and maintenance-free. An average power consumption of 400 Watts requires energy costs amounting to less than 3 cents/hour. The integrated diagnostic system shows the device's status. Either modules or the whole device can be exchanged fast and easily.

cablase provides both a multilingual user interface and a freely programmable COM interface. The software can be installed on a standard PC without any additional PC interface cards under the operating systems Windows NT, Windows 2000 or Windows XP. Additionally, an extensive library which contains control commands for the laser system and scanning head helps to respond to even complex demands as for example "marking on the fly". cablase offers in addition the possibility to control and to supervise external NC axes and digital in- and outputs. The processing of variable data as well as access to external data bases is given. The integrated "live" preview supports the user to manage his jobs.

Add a Comment

No messages on this article yet