Murata Electronics has announced a tiny RFID (radio frequency identification) chip that will substantially reduce manufacturing complexity and costs for paper tag inlays in asset tracking, retail and supply chain management applications.

Called Magicstrap, the electronic chip can be mounted onto a foil antenna pattern in a paper UHF tag inlay using ordinary non-conductive glue or sticky tape, and is said to require only minimal placement accuracy, so this can even be done by hand. Magicstrap is also claimed to enable "Zero Defect" manufacturing of these tags in a quick, easy and flexible way.

Called Magicstrap, the electronic chip can be mounted onto a foil antenna pattern in a paper UHF tag inlay using ordinary non-conductive glue or sticky tape, and is said to require only minimal placement accuracy, so this can even be done by hand. Magicstrap is also claimed to enable "Zero Defect" manufacturing of these tags in a quick, easy and flexible way.

In Magicstrap Murata has utilised its materials knowledge and high-frequency module technology to create a durable, stable and easy RFID solution that will enable widespread adoption of the UHF RFID tags for all applications.

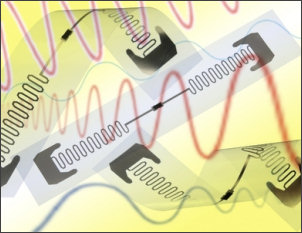

The overall dimensions of the new Magicstrap chip for item level tagging are a tiny 1.6 by 1.2 by 0.25 mm. A typical RFID system inside a paper tag or tag inlay would comprise the Magicstrap chip glued onto an antenna pattern made of thin conductive metal foil. Murata has a standard reference design for this antenna pattern so no prior knowledge or expertise in RFID electronics is necessary for manufacturing the tags.

Magicstrap is readable over the band 860-960MHz with a long read distance of up to 5m. This means the same tag design can be used worldwide (in Europe, the US and Japan), saving inventory for manufacturers. Magicstrap complies with EPC Global Gen 2.

Add a Comment

No messages on this article yet